Your basket is empty.

Look like you haven't added anything to your cart

It’s estimated that a staggering 33 billion pounds of plastic waste makes its way into oceans around the world each year. This astonishing amount has devastating consequences for marine life and the cleanliness of our oceans. With this in mind, the team here at LifestyleGarden® is committed to doing our part to reduce this impact in any way we can.

DuraOcean® and Social Plastic® are two recycled materials that we use here at LifestyleGarden®, helping us to craft quality and durable outdoor furniture.

In order to guarantee that our products have a minimal environmental impact, we decided to work with these two materials, as they are preventing plastic to enter the oceans and, in the case of Social Plastic®, providing benefits to local communities around the world.

In this article, we’ll explore how DuraOcean® and Social Plastic® innovatively manufacture recycled and recyclable plastic furniture.

Before we take a closer look at how we manufacture our products with DuraOcean® and Social Plastic®, let’s focus on how plastic can be recycled.

Not all plastics can be recycled, but there are two key methods for those that can. These are:

1. Mechanical Recycling

Mechanical recycling is the easiest way to recycle plastic. This process involves plastic being heated and softened into moulding granules which can be used to create new products. These granules are then cleaned, re-compounded with additives and chopped into small pellets for reuse.

2. Feedstock Recycling

Conversely, feedstock recycling breaks down polymers into parts via heat or intense pressure. Then, these parts will be used to make new plastics and chemicals. This is a particularly beneficial process when the plastic that is being recycled has been mixed or contaminated in any way.

DuraOcean® is one of the world’s most innovative and forward-thinking recycled plastic materials. It uses recycled rope from the maritime industry, preventing them from entering oceans and causing environmental harm.

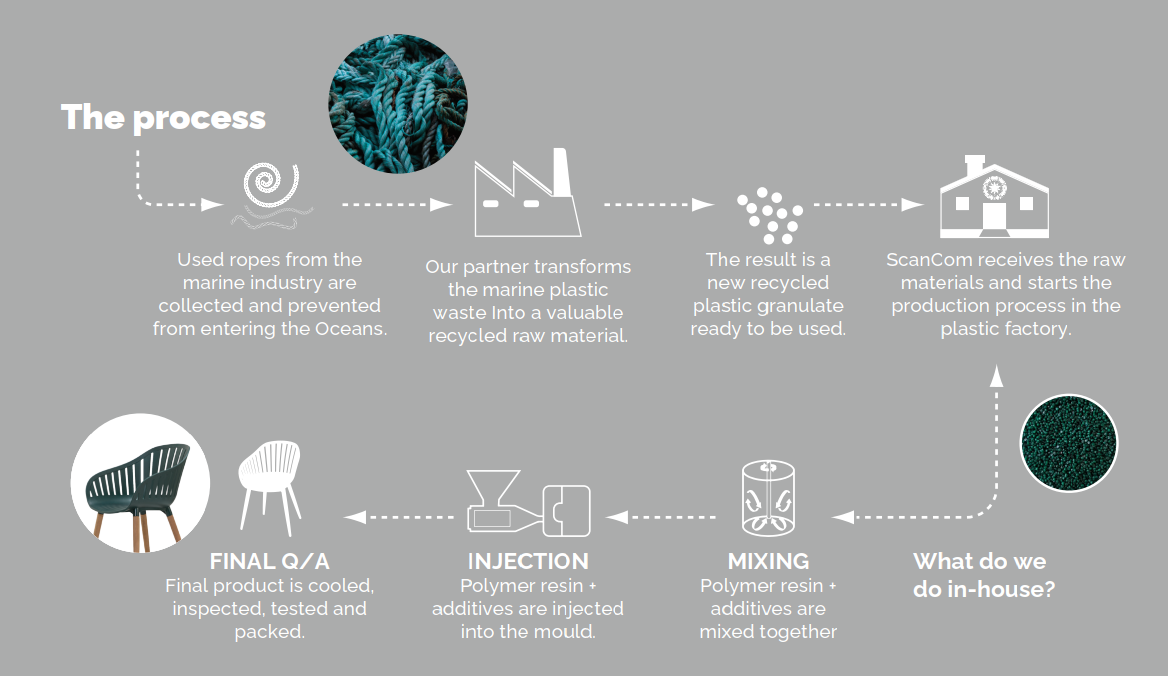

The process begins with the DuraOcean® team collecting ropes from the ports and preventing them entering the ocean. The waste is then transported to our partner’s factory where it is converted into raw materials, resulting in newly recycled plastic granules that are ready for use.

Next, the production process can begin in our own plastic factory. This involves polymer resin and additives being mixed together, before being gas injected into the new product mould. The final product is then cooled, inspected, tested and packed ready for purchase.

Plastic Bank is a global organisation that recognises how plastic pollution and poverty are intertwined. With this in mind, they’ve helped empower local communities across the world by encouraging people to recycle plastic waste at local centres where they’re treated as currency. In exchange, people are provided with a whole host of benefits including groceries, cooking fuel, school tuition, health services and much more. This process means that people in poverty receive key services while simultaneously keeping plastic waste out of oceans.

The plastic is then recycled by Plastic Bank into a product known as Social Plastic®. Social Plastic® has gone on to be used as a material for a multitude of products and packaging, including outdoor furniture that LifestyleGarden® sells. Since the brand’s inception, it has supported local communities in some of the poorest parts of the world including Brazil, the Philippines and Indonesia.

At LifestyleGarden®, you can see recycled materials used across our extensive product range. In particular, our Nassau range utilises recycled plastic from both DuraOcean® and Social Plastic® materials to combine an innovative aesthetic and sustainability.

To find out more about our role in tackling plastic waste as well as to explore our range of stunning outdoor furniture products, get in touch with us today.